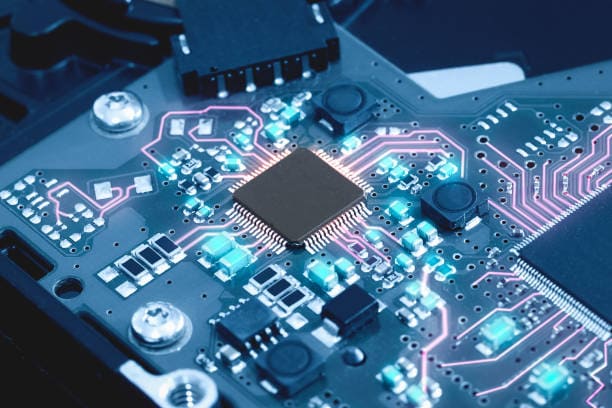

Surmotech’s skilled staff manufactures complex printed circuit board assemblies (PCBA) providing technical solutions which meet or exceed our customers requirements.

- SMT, AOI

- X-ray for bottom terminated devices

- Selective soldering

- Wave soldering

- Conformal coat

- Specialized hand soldering

Our highly qualified technical staff works with your team to develop and define robust solutions.